By SuperyachtNews 25 Nov 2011

Bristol Yacht Components installs new carbon fibre stair system on Independence II

Bristol yacht components have installed their new carbon fibre stair system, the company’s premier product line from august, on motoryacht independence ii.….

Join the discussion

To post comments please Sign in or Register

When commenting please follow our house rules

Click here to become part of The Superyacht Group community, and join us in our mission to make this industry accessible to all, and prosperous for the long-term. We are offering access to the superyacht industry’s most comprehensive and longstanding archive of business-critical information, as well as a comprehensive, real-time superyacht fleet database, for just £10 per month, because we are One Industry with One Mission. Sign up here .

Sign up to the SuperyachtNews Bulletin

Receive unrivalled market intelligence, weekly headlines and the most relevant and insightful journalism directly to your inbox.

Sign up to the SuperyachtNews Bulletin

The superyachtnews app.

Follow us on

Media Pack Request

Please select exactly what you would like to receive from us by ticking the boxes below:

SuperyachtNews.com

Register to comment

Bristol Yacht receives patent for stairs

Essex, Connecticut, USA –– Exclusive Yacht Sales, L.L.C., the parent company of Bristol Yacht Components, was recently assigned a U.S. Design Patent for the company’s Bristol Boarding Stairs™. The patent, No. US D664,494 S, was issued on July 31, 2012.

According to the company, Bristol Boarding Stairs blend innovative engineering, advanced carbon fiber technology, and marine-proven materials to provide a reliable, lightweight, safe access system for motor and sailing yachts. Bristol Boarding Stairs are self-leveling, easy to deploy and stow, and are available in 4 to 14-step units.

“We are very pleased with the U.S. Patent Office’s favorable review of our application,” says company president, Todd Schenk. “The unique design of our system contributes to its durability, ease of operation, enhanced safety and performance, with a look that blends modern industrial design with classic yachting elements such as inlaid teakwood and polished stainless steel.” For more information, or a custom price quote, contact Bristol Yacht Components at 860-883-4904, or online at www.bristolyachtcomponents.com.

Related Posts

The U.S. Patent and Trademark Office has granted a patent for an app that will operate a yacht, a concept created by Apple founder Steve…

A 20-year-old male was taken to a West Palm Beach trauma center on Tuesday(May 24) after being shocked while working on the electrical system of…

Lürssen launched, on April 5, the 590-foot (180m) M/Y Azzam, the world’s largest yacht. Steel was cut for the hull 28 months ago. The yacht…

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Boat Review Forum

- Boat Reviews

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Thoughts on Bristol Yachts?

- Add to quote

Hello I am on the lookout for an affordable yacht which is seaworthy as well as attractive to look at. The Bristols are increasingly catching my eye, and the 38.8 looks like a reasonably modern, solid and attractive boat. I would appreciate any insights about how she sails - including in stiffer breeze or gale - and any other observations or tips. Also very interested in views about build quality and issues to look out for when buying used - e.g. I am unfamiliar with keel/centreboard designs and wonder if there is anything to have in mind there when searching/surveying. thank you for any insights! Julian

Bristols we've raced against tend to be slow. They tend to be heavy, needing a good breeze (20 knots +/- ) to get moving. They also tend to be well put-together, sturdy boats. Friends had a 35.5 which they sailed for years with the centerboard up. Other friends with a 35.5 also don't race, and probably don't use their centerboard either. Still other friends with a 45.5 do race, (slowly, unless it's blowing 20+ ) but it is a fixed keel version.

They have a good reputation.... Ask Jeff H

I have a 35.5, but the build, concept, set up etc. is similar to a 38.8. It's not a "performance" or racing boat by any means. But I certainly can get up to 6.5 knots at much less than the 20 knots of wind that is referenced above (you need to deepen the mainsail in lighter wind (need good outhaul set up)), so don't get put off by any commentary that it is not a "light" air boat . I sail in Chesapeake Bay in August with no problems, but I'm not a racer or "performance cruiser" so my perspective may be different. Mine is built like a brick sh*ter. It gets on a rails and runs. Look at other boats, and you'll appreciate the build quality of these Bristol "decimal series" boats. MIne is a CB model - need to keep the pivot point and cable mechanism inspected/serviced regularly.

Sheerline said: Hello I am on the lookout for an affordable yacht which is seaworthy as well as attractive to look at. The Bristols are increasingly catching my eye, and the 38.8 looks like a reasonably modern, solid and attractive boat. I would appreciate any insights about how she sails - including in stiffer breeze or gale - and any other observations or tips. Also very interested in views about build quality and issues to look out for when buying used - e.g. I am unfamiliar with keel/centreboard designs and wonder if there is anything to have in mind there when searching/surveying. thank you for any insights! Julian ( [email protected] ) Click to expand...

bristol299bob said: I've owned my Bristol 29.9 for 14 years and have been impressed with it. The build quality is excellent, the interior is warm and cozy, the classic lines are (to my eye) quite lovely. I get frequent comments on how good looking the boat is. When we are in heavy weather (inshore or offshore) we feel safe and confident in the boat. And we can go down below off watch and the boat is quiet and we can get real rest. There are no creaks, rattles, or flexing. just the sound of water rushing by and the thump of a wave. I've been on a number of boats that make quite a racket down below and it's hard to get rest (for the noise and, worse, for the wonder of "is that noise the sound of something about to break"). FWIW my boat happens to be for sale: For Sale - Bristol 29.9, 1977, Hull #5 - S/V Surprise Click to expand...

Thanks to all of you - these are useful insights. Much appreciated! I will take a closer look. The boat will be used on the Chesapeake mostly (we live in DC) and hopefully some longer runs beyond - soon. What do people think of the Bristol 39 and 40? I imagine they are not great at pointing, underpowered SA/D, but look rather nice and also solidly built, and a lot of boat for your money.

I've owned my Bristol 29.9 for 14 years and have been impressed with it. The build quality is excellent, the interior is warm and cozy, the classic lines are (to my eye) quite lovely. I get frequent comments on how good looking the boat is. When we are in heavy weather (inshore or offshore) we feel safe and confident in the boat. And we can go down below off watch and the boat is quiet and we can get real rest. There are no creaks, rattles, or flexing. just the sound of water rushing by and the thump of a wave. I've been on a number of boats that make quite a racket down below and it's hard to get rest (for the noise and, worse, for the wonder of "is that noise the sound of something about to break"). FWIW my boat happens to be for sale: For Sale - Bristol 29.9, 1977, Hull #5 - S/V Surprise

| 38.25 | 37.67 | 38.25 | |

| 30.58 | 30.5 | 31.2 | |

| 12.08 | 12.0 | 10,600 | |

| 4.5 | 6.5 | 6.4 | |

| 19,150 | 14,900 | 10,600 | |

| 299 | 234 | 156 | |

| 16.7 | 18.8 | 22.9 | |

| 47% | 42% | 39% |

Jeff_H said: Like many boat builders, both the design and build quality of the various Bristol models vary a lot. The 38.8 came into existence late in the company's existence and at a time when Bristol's design and build quality had improved enormously from its earlier boats. Because of that, rather than a broader discussion of Bristol Yachts, I will therefore focus on the 38.8 specifically and touch on the keel-centerboard a little. The Bristol 38.8 was designed by Ted Hood and Dieter Empacher with a specific concept in mind. During the IOR II rating rule era a number of designers had explored a rating advantage by designing boats that were excessively heavy by any relative standard, and which had comparatively small rated sail plans. The concept was to offset the liability from excessive weight by minimizing drag. In this design theory drag was reduced by using essentially cylindrical cross sections and that helps a lot. But in and of itself, cylindrical cross sections do nothing good for stability or motion comfort since they provide minimal form stability until the topsides are in the water and almost no damping to suppress the tendency to roll. As a result these boats needed (and were given) a very high ballast ratio which helps some with stability. Similarly, because of the way that race boat ratings were the foretriangle was made huge and that allowed for a lot unpenalized sail area to be carried in large overlapping genoas and enormous spinnakers. When combined with the the low drag hull forms, these boats sail much better than their numbers might suggest. But that comes at a price. These boats require much larger sail area than a lighter boat and therefore are more physically demanding than a typical 38 footer of the era. Also those large overlapping headsails do not adapt well to changing conditions. Still the Bristol's 'numbers' are way outside of what would have been considered normal back when this boat was designed and are even more extreme when compared to current yacht design science. It is probably best to illustrate this with a two more examples of 38 footers of this era whose design brief was a performance cruiser with offshore passage making capabilities. The two other two are performance cruiser the Ericson 38 and the Farr 11.6. Bristol 38.8 Ericson 38 Farr 11.6 LOA 38.25 37.67 38.25 LWL 30.58 30.5 31.2 Beam 12.08 12.0 10,600 Draft 4.5 6.5 6.4 Displacement 19,150 14,900 10,600 D/L 299 234 156 SA/D 16.7 18.8 22.9 Ballast Ratio 47% 42% 39% The Ericson was at the high end of normal weight and had sail area that was reasonably consistent with most performance cruisers of the era and frankly is pretty close in weight and SA/D to a modern 38 foot performance cruiser. The Farr is at the extreme low end of the weight for a performance cruiser and at the higher end of the sail area to displacement in large part since it was not designed to beat any rating rule. It is important to understand that weight does absolutely nothing good for a boat. It does not make it more seaworthy, it does not improve motion comfort, it does not add stability, and it does not make it stronger. But weight does increase the working loads on the boat, it does make it physically harder to handle, it makes maintenance more expensive, and it hurts performance and fuel consumption. But this is where things become more subjective, Some of that weight was put into lovely little details like custom made, chrome on cast-bronze hardware. Some of that weight went into heavier interior components and truly lovely cabinetry. Some went into a heavy duty teak toe rail, cast bronze portlights, and stainless steel guardrails. Some of that weight went into bigger water and fuel tanks. And most significantly some of that weight (3,000-4,000 lbs) went into having a much larger ballast ratio in order to allow a shallower draft. I also want to touch on the keel center-board. I see keel centerboards as being a great way to optimize upwind performance while having shallower draft when motoring or in port. The convenience is enormous if you sail in a shallow venue. Centerboards can be partially raised to balance the helm or reduce heeling a little (at the price of leeway). They can be a little more maintenance, but i have never heard of Bristol 31.1, 35.5 38.8, or 41.1's having difficult maintenance problems with their centerboards. That is about it for now, Jeff Click to expand...

Blue water boat... you are on the right track.

thanks!

- ?

- 176.1K members

Top Contributors this Month

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Maine Cat 41 Used Boat Review

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Working with High-Tech Ropes

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate: Part 1

Whats the Best Way to Restore Clear Plastic Windows?

Mastering Precision Drilling: How to Use Drill Guides

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

Chafe Protection for Dock Lines

- Sailboat Reviews

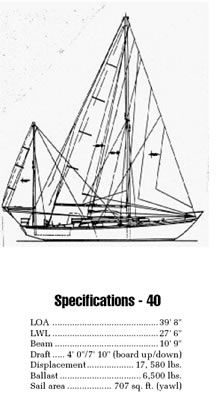

Bristol 39/40

The looks of these twins are strictly traditional, but so is the interior room modern 33-footers have more..

The Bristol 39 and Bristol 40 are basically the same boat, even though the specifications state that the Bristol 40 is nearly a foot longer than the Bristol 39. According to the builder, the hull sections aft were made slightly fuller on the Bristol 40, and the stemhead fitting was altered. After very careful scaling of plans, we can say with reasonable confidence that from one end of the hull to the other, excluding the bow pulpit and the anchor roller, the Bristol 39 and Bristol 40 are about 39′ 8″ long. Whether you call it a 39-footer or a 40-footer is up to you.

But this is not a 40′ boat in the modern sense. Yes, if you take a tape measure to the boat, you’ll read almost 40′. But if you go below, you’ll swear you stepped onto a 33′ boat—at least if you’re used to looking at the 33-footers built today.

With a waterline length of 27′ 6″ and a beam of 10′ 9″, The Bristol 40’s proportions are about as typical as you can get of cruising/racing sailboats built between about 1930, when the CCA (Cruising Club of America) rule was conceived, and 1970, when it was replaced by the International Offshore Rule (IOR). For those 40 years, about 30% of the average boat’s length was in overhangs. Today, you find the waterline length and beam of the Bristol 40 on boats less than 35′ long.

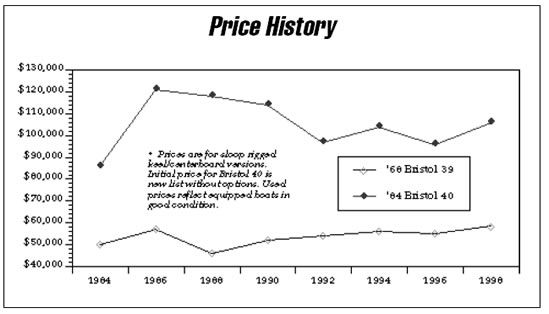

About 150 Bristol 40s were built. This does not include the relatively small number of boats in the Bristol 39 series.

The 39 was one of the first models built by Bristol Yachts, entering production in 1966. Beginning with 1972 models, the boat was rechristened the Bristol 40. The last Bristol 40 was built in 1986.

If you like traditional yachts, you’ll find the Bristol 40 appealing. The boat has the long overhangs, lovely sheerline, low freeboard, narrow cabin trunk undistorted hull shape, and narrow beam we associate with the beautiful yachts of the past. If you didn’t know she was a Ted Hood design, you might mistake her for a boat by Olin Stephens, John Alden, or Phil Rhodes. The trade-off for these traditional good looks is a boat with a small interior compared to today’s 40- footers.

Sailing Performance “Fast” is a very relative term when you’re talking about sailboats. The Bristol 40 is not fast relative to more modern 40-footers, but her performance is similar to that of other boats of her length built under the CCA rule, when boats were heavier and shorter on the waterline than they are today. The boat is close in speed, for example, to the Hinckley Bermuda 40 yawls with the original low aspect ratio rig. It is about 30 seconds per mile slower, however, than the Cal 40—a boat of the same length on deck, but with a longer waterline, less wetted surface and slightly less displacement.

In both keel and centerboard versions, the Bristol 40 is a fairly tippy boat, as you would expect from her narrow beam, shoal draft, and modest amount of ballast. Like “fast,” however, “tippy” is a relative term.

Most narrow boats have relatively low initial stability, even if their ultimate stability is good. For example, the McCurdy and Rhodes 62-footer Arcadia, built in 1972, is about 2′ narrower than a new IOR 60- footer would be, and has a righting moment about 15% lower than that of the new boat, even though Arcadia is significantly heavier.

Yet Arcadia’s range of positive stability is about 143°, while the typical “modern” racer/cruiser loses positive stability at 120° or less.

Unfortunately, being narrow and tippy doesn’t guarantee a good range of ultimate stability. The keel version of the Bristol 40 loses positive righting moment at about 120°—the absolute minimum we would consider for a serious offshore cruiser. The centerboard version’s range of stability is less—about 110° for the only boat rated under the International Measurement System (IMS).

It is not unusual for centerboarders to have very low positive stability. The Hinckley Bermuda 40— the classic keel-centerboarder—typically loses stability at an even lower angle than the centerboard Bristol 40, yet few people would consider the boat unsuitable for passage making.

Owners report that the Bristol 40 is very sensitive to the amount of sail carried. We’d suggest a modern headsail reefing/furling system for shorthanded cruising to reduce the number of headsail changes required. Like most CCA boats, the Bristol 40 is a good reaching boat, lacking the rounding-up tendency of many modern boats with full sterns. The trade-off is that the boat tends to squat when running downwind, digging a hole that’s hard to climb out of. A Bristol 40 with a full keel won the 1983 Marion- Bermuda Race, an event that consisted largely of four days of close reaching in light to moderate breezes.

Because the boat is narrow, there is no need to move the genoa track inboard of the toerail. The only real disadvantage of toerail-mounted genoa track is that you may have to relead the sheet to clear stanchions when changing headsails or reducing sail area with a headsail furler, unless there are turning blocks at the aft end of the genoa track.The two most common mainsheet arrangements on the boat are a short traveler spanning the cockpit immediately in front of the steering wheel, or a longer traveler over the coachroof in front of the companionway. The short traveler in the cockpit doesn’t really offer much mainsail control, but it is a convenient location for the sheet.

The rig is a basic masthead sloop or yawl, using an untapered, keel-stepped anodized mast with single spreaders and double lower shrouds: basically foolproof. The lower shroud chainplates do not line up exactly with the pull of the shrouds, which will tend to fatigue the chainplates over time, as well as increasing the likelihood of leaks due to an unfair pulling angle.

Since this is a boat that was in production for the better part of 20 years, it’s difficult to generalize about the sailing gear you’ll find. On the Bristol 40s we’ve looked at, the stock winches tend to be one or two sizes smaller than we’d put on the boat today. You’re unlikely to find self-tailers on older models.

A lot of Bristol 40s were built as yawls. While the yawl rig is pretty and looks very traditional, the mizzen is generally only useful to help balance the helm, as a convenient place to mount a radar antenna, and to serve as a support for a mizzen staysail on the rare occasion that it pays to carry one. The mizzen makes the boat more tippy and increases windage—disadvantages for upwind sailing.

Engine Before 1970, Bristol 39s came with either Atomic 4 or Graymarine gas engines. Later model 39s and Bristol 40s were powered either by the Atomic 4 or by a variety of diesels, including the Westerbeke 4-91, Westerbeke 4-107 and 4-108, Perkins 4-108, or Volvo MD2B and MD3B engines. That should be enough variety to satisfy everyone.

The Westerbeke and Perkins 4-108s are essentially the same engine, and in our opinion would be the best engine for the boat, although they’re more power than it needs. Diesel engine installations in the Bristol 40 are not without problems. There is little room between the shaft coupling and the stuffing box—so little, in fact, that several owners surveyed reported that it is almost impossible to reach the stuffing box for adjustment or repacking.

In all models, the fuel tank is located under the cockpit sole, above the engine. Fuel capacity is about 30 gallons. Early diesel-powered models have black iron fuel tanks, and at least one owner surveyed reported having to replace a rusted-out tank after a years. Later models have aluminum fuel tanks, which are less likely to corrode. Range under power with the Perkins 4-108 and 30 gallons of fuel will be about 180 miles.

The gasoline engines used in early models swing a small prop. Unfortunately, when the switch was made to bigger diesels—the Perkins 4-108 displaces 108 cubic inches, the Atomic 4 only 65 cubic inches— the propeller aperture was not enlarged, limiting prop size. We measured the height to be 16 1/2″, which means you can really only swing about a 15″ prop and still maintain adequate tip clearance. The result is that you end up turning an oversquare prop (more pitch than diameter), which is not the most efficient way to utilize the engine in a sailboat.

Our prop choice would be a three-bladed feathering Maxprop for the best combination of performance under both sail and power. The Maxprop would also slightly improve handling in reverse, which is rated as poor by most owners. A tiny fixed prop tucked in an aperture in the deadwood and rudder is a bad combination for handling in reverse. Powering ahead, the boat handles just fine.

There is no sound insulation in the engine compartment. Access to the front of the engine is fair, requiring removal of the front of the engine box which doubles as the companionway ladder.

Construction Bristol Yachts has gone through a lot of changes over the years. The prime mover behind Bristol was Clint Pearson, one of the pioneering Pearson brothers— the other, Everett, now runs Tillotson-Pearson.

The boats built by Bristol today are a far cry from those of 15 years ago. Current Bristols are targeted toward the middle to upper end of the production and semi-custom markets, with very good finish detail and systems. Originally, Bristols were aimed at the mass market, and were finished and equipped accordingly.

Since the Bristol 40 was built over a period of 20 years, there were a number of minor changes during the production run, but the last boats are essentially the same as the first ones.

The Bristol 40 is not a particularly lightly built boat, but she is certainly not heavy for her overall length, even by modern standards. The boat is substantially lighter than most long-keel CCA 40-footers. The Hinckley Bermuda 40, for example, displaces about 20,000 pounds in normal trim. The Cal 40, considered a real lightweight in 1966, weighs about 16,000 pounds in IMS measurement trim; the average Bristol 40, right at 17,000 pounds in the same configuration.

By way of comparison, the Little Harbor 38 that won the 1986 Newport-Bermuda Race tips the scales at a hefty 25,000 pounds, and the newer Bristol 38.8 has a designed displacement of just over 19,000 pounds.

None of the Bristol 40 owners we surveyed report any major structural flaws. They do, however, complain of annoyances such as leaking ports, deck hardware, and hull/deck joints. These are generally assembly and quality control problems, and most can be solved by the owner, albeit with a fair amount of labor. A leaking hull/deck joint may be more of a problem, but this type of leak should show up during a careful examination of the boat. Discoloration and water streaks inside lockers and on bulkheads, rust and drips on through-fastenings, and mysterious puddles of water may indicate leaks in the joint.

From a cruiser’s point of view, a nice feature of the Bristol 40 is its water capacity: 130 gallons in two fiberglass water tanks.

Any sailboat hull older that about eight years is getting on toward being a candidate for painting. While the gelcoat in the Bristol 40s we examined still looks reasonable, most of the colored hulls—pastels were popular in the 70s—are badly faded. The colored gelcoat used was not colorfast.

We also noted numerous gelcoat flaws on decks cracks around stanchion bases, some voids at sharp corner transitions. During the survey, the surveyor should carefully sound the entire deck for voids. If you’re going to go to the trouble and expense of painting, you might as well catch all the problems at the same time.

Deck non-skid is a molded-in basket weave pattern, and we have found it to be less effective than more aggressive non-skid designs.

The cockpit is huge, with seats almost 7′ long. The well is narrow enough that you can brace your feet against the opposite seat—a good feature on any boat, but especially important on a tippy boat. The big cockpit is a mixed blessing. It gives plenty of space for daysailing or in-port parties, but it is also vulnerable to filling in extremely heavy offshore conditions.

In our opinion, the cockpit scuppers are too small. Each of the two scuppers is about the size of a bathtub drain. Since there is no bridgedeck—just a raised companionway sill—it is particularly important that the cockpit drain quickly. This is a pretty reasonable retrofit job. For offshore sailing, the bottom dropboard should be caulked and permanently secured in place.

There is a reasonable amount of exterior teak trim on the boat, including toerails, cabin eyebrow trim, handrails, and cockpit coamings. A Bristol 40 with a freshly-Awlgripped hull and varnished teak trim would look handsome, indeed.

On the port and starboard quarters, there are large chocks for dock lines. While these look substantial, they are only screwed to the toerails, and can easily tear out. Chocks can be very heavily loaded during panic dockings, and should always be through-bolted, as should all deck hardware.

Through hull fittings are not recessed flush, but can easily be faired in to reduce drag in very light air. The Constellation-style rudder is set slightly above the aft edge of the keel, so that the boat will ground out on the keel rather than the rudder.

Instead of a bolt-on external keel, the Bristol 40 has a molded keel cavity filled with 6,500 pounds of lead. One owner we surveyed had added 1,500 pounds of lead pigs in the bilge to improve stability.

Interior Bristol has always made extensive use of built-up interiors of plywood and solid wood, rather than fiberglass molded components trimmed out in solid wood. The company has also made extensive use of mahogany rather than teak in interior construction.

If you’re used to the dull brown of teak, the brighter reddish-brown of the mahogany interior of the Bristol may or may not appeal to you. Mahogany must be varnished: it is not suited to an oil finish in a marine environment. If you let the varnish wear off, the wood will turn grey, particularly after exposure to water.

At the same time, mahogany is lighter and brighter than teak, and can make an all-wood interior slightly less gloomy. If all else fails, you can always paint out the mahogany bulkheads and leave the mahogany trim varnished. Teak plywood is much harder to paint out, since its waxy surface doesn’t hold paint very well.

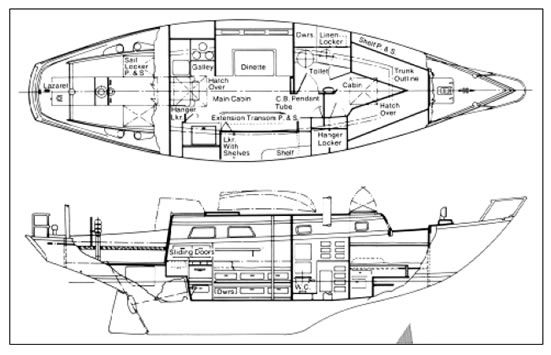

The built-up interior allowed a number of interior options in the Bristol 39 and 40. As originally drawn, the boat had a wide-open offshore racing interior, with a sail locker forward, the head in the area normally reserved for a forward sleeping cabin, and symmetrical pilot berths, settees, and quarterberths in the main cabin. While it provides six sea berths, this interior has little appeal for a cruising family. Most boats were built with one of several more conventional interior layouts.

One advantage of long-ended boats is that the Vberths don’t have to be jammed into the bow. Instead, you get berths that are wide enough at the foot for normal-sized people. The forward cabin of the Bristol 40 is quite roomy, with two berths and various lockers and drawers. An insert turns the V-berths into a reasonable double berth.

The head compartment is aft of the forward cabin, on the port side. It is a big, roomy head, with rather remarkable storage, including 10 small drawers and three lockers. All boats came with hot and cold pressure water, and have a hand-held shower attached to the head sink fixture.

Opposite the head are the usual hanging lockers.

Several different main cabin layouts were offered, with an arrangement to please just about every fairly conventional taste. On the port side, you’ll find either a settee berth with storage outboard, a Ushaped dinette, or a narrow pull-out settee with a pilot berth outboard. On the starboard side, you’ll usually find a settee with a folding pipe berth above, although some boats were built with a conventional pilot berth outboard of the starboard settee.

On boats without a dinette, the main cabin table folds up against the port forward bulkhead—a reasonable solution in a narrow boat.

Main cabin storage space is quite good, with a number of drawers and lockers. The actual storage arrangement varies with each interior layout.

Ventilation in the main cabin, as well as in the entire boat, is so-so. There is an opening port in the head, and a cowl vent overhead. There is another cowl vent on the other side of the cabin trunk opposite the head, providing some air to the forward cabin and main cabin in foul weather. Over the forward cabin is a large fiberglass hatch.

A fiberglass hatch over the main cabin was optional. The main cabin ports do not open. Ventilation would be greatly improved by adding Dorade boxes just in front of the dodger breakwater at the aft end of the main cabin. If you also put a reversible aluminum-framed hatch directly over the middle of the main cabin, and added a small dodger to it for heavy weather protection, you’d go from lousy ventilation to good airflow in one fell swoop.

We’re not keen on the fiberglass hatches used in production boats in the 1970s. They distort easily, and never seem to seal completely.

Headroom is about 6′ 4″ on centerline aft, decreasing to about 6′ in the forward cabin.

In all interior layouts other than the original ocean racing one, the galley is at the aft end of the main cabin. There are two aft galley arrangements. One is spacious but not particularly efficient, the other is tight. On boats equipped with a quarterberth and nav station on the port side, the galley is jammed into the starboard aft corner, and is small for a 40-footer. On boats without a nav station, stove and sink are on the port side, with a large icebox opposite to starboard. The top of the icebox is then used as a navigation table. Neither galley layout is as good as the Ushaped galley used on more modern boats such as the Bristol 38.8.

You’ll have to make a choice on the galley layout. A nav station is very desirable if the boat is used for more than daysailing. Yet the starboard galley you get on boats with nav stations is quite small, and doesn’t have much storage for foodstuffs or utensils.

Even on boats with the port nav station, the electrical panel is located on the starboard side, above the galley and next to the companionway, in a fiberglass box that’s a molded part of the cabin liner. We’d want to give better protection to the panel by building a frame with an opening clear acrylic cover.

Despite the narrowness of the Bristol 40 compared to newer boats, the interior is reasonably laid out and not cramped. Headroom is good, and you can easily make improvements in ventilation. The interior doesn’t seem as spacious as a lot of boats due to the fairly narrow, tall cabin trunk. Newer designs have more freeboard, allowing a lower cabin trunk and increasing the feel of interior space.

Conclusions Like the better-known Bermuda 40, the Bristol 40 is an exceptionally pretty boat, and those good looks are one factor that kept the boat in production for such a long time. But the Bermuda 40 has been carefully refined, and its reputation nurtured by a group of nearly-fanatical owners who are willing to pay rather remarkably high prices for a design that is now 30 years old.

The Bristol 40, on the other hand, lacks that reputation and following. A few Bristol 40s were built for die-hards even after the boat was superseded in 1983 by the faster, roomier, stiffer Bristol 38.8—a design that is a distinctly more modern Hood cruiser/racer.

Because of her large cockpit, small cockpit drains, slightly vulnerable companionway, and fairly low initial stability, this boat wouldn’t be a good choice for extended offshore cruising, although Bristol 40s have certainly done their share of it. For cruising in the Chesapeake, Bahamas, or Gulf of Mexico, the keel-centerboard version would be a reasonable choice, and even the deep keel model draws substantially less than most 40-footers.

A late-model, sloop-rigged boat with Perkins or Westerbeke diesel would be our first choice. Since relatively few changes were made in the boat during the years of production, however, you might also find a good older boat on which a lot of attention has been lavished.

If you like traditional looks, and you cruise in shoal coastal waters without extremely heavy winds a lot of the time, the Bristol 40 should appeal to you. You’re a natural candidate for the boat if the looks of the Bermuda 40 catch your eye, but you don’t have the pocketbook to indulge yourself in Hinckley quality.

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

What’s the Best Sailboats for Beginners?

Why Does A Sailboat Keel Fall Off?

The Perfect Family Sailboat! Hunter 27-2 – Boat Review

Pettit EZ-Poxy – How to Paint a Boat

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

Bristol Yachts

Clint Pearson launched Bristol Yachts in the fall of 1964 after he stepped out of the presidency of the Pearson Yachts, which had become a division of Grumman Allied Industries. After purchasing the assets of Sailstar Yachts, another manufacturer of small sailboats in the area, he also bought the Poppasquash Point boat yard and the land on Franklin Street to establish a manufacturing plant. Here he built the first new models like the Bristol 27, designed by Carl Alberg. In one year 172 Bristol 27’s were built. There was also the Bristol 29 designed by Halsey Herreshoff, the Bristols 32 and 39 designed by Ted Hood, and Bristol 34 designed by John Alden Assoc.. Later ‘second generation’ models included the 31.1, 35.5, 41.1, 45.5, 47.7 and then larger custom boats. In total, 4400 Bristol Yachts were produced between 1965 and 1997 when the company ceased production. HIN for Bristol Yachts: BTY

Associations

- Bristol 27 Site

- Half Ton Class

- Boatbrochure.com (orig. brochures and manuals)

- Bristol 29 Owners (USA)

- Carl Alberg

- Clifford Swaine

- David Pedrick

- Dieter Empacher

- Halsey Herreshoff

- John G. Alden

39 sailboats built by Bristol Yachts

Sailstar Bristol 24 Corsair

Bristol 19 (Sailstar Corinthian 19)

Bristol 22 Caravel

Bristol 29.9

Bristol 35.5

Bristol 41.1

Bristol 38.8

Bristol 47.7

Bristol 27.7

Bristol 43.3

Bristol 33.3

Bristol 48.8

Bristol 54.4

Bristol 31 XL

Bristol 3800

Bristol 56.6.

Corinthian 19 (Alberg)

Bristol 27-2

Bristol 27 (Weekender)

Bristol 45.5 CC

Bristol 45.5

Bristol 51.1

Bristol 31.1

Bristol 43/44

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Bristol Yacht Refinishing

YACHT REFINISHING

Service details.

Bristol Yacht Refinishing stands out from the competition with our expert team of craftsmen, dedication to quality and top of the line marine products and over 25 year of experience in the industry. We have worked around the world working on different projects and have the knowledge and team to get the job done. From bottom jobs to full refits and paint jobs there is nothing to big or to small at Bristol.

OTHER serviceS

custom proyects

POLISHED TO PERFECTION

IMAGES

VIDEO

COMMENTS

Bristol Yacht Components manufactures boarding stairs for yachts of all sizes and styles. Bristol Boarding Stairs are made from strong, lightweight carbon fiber. They blend innovative design, pleasing aesthetics, and advanced engineering to provide beautifully crafted access for both motor and sailing vessels. Discerning yacht owners, yacht builders, captains and crew will appreciate the fine ...

Bristol Yacht Components manufactures boarding stairs for yachts of all sizes and styles. Bristol Boarding Stairs are made from strong, lightweight carbon fiber. They blend innovative design, pleasing aesthetics, and advanced engineering to provide beautifully crafted access for both motor and sailing vessels. Discerning yacht owners, yacht builders, captains and crew will appreciate the fine ...

Bristol Yacht Components™ was founded in 2011 with a company mission to provide component and accessory products for yacht owners and manufacturers, worldwide, that enhance the yachting experience through advanced engineering, reliable functionality and artful design. From design to delivery, this mission is reflected in our premier product ...

Jun 28, 2012. A new company in the yachting equipment marketplace, Bristol Yacht Components, has introduced its premier product line: Bristol Boarding Stairs. Bristol Boarding Stairs are made of carbon fiber to provide a durable, lightweight, easy-to-deploy access system with an aesthetic design to enhance the look of any motoryacht or sailing ...

Bristol Yacht Components have installed their new carbon fibre stair system, the company's premier product line from August, on motoryacht Independence II.… Previous Next In August earlier this year, Bristol Yacht Components, a new company in the yachting equipment market, introduced its premier product, Bristol Boarding Stairs.

Bristol Yacht Components' high-end boarding stairs are made of carbon fiber to provide durable, lightweight access while enhancing the look of your. Skip to main content. Digital Boat Show. Under 40' Vessels 40'-80' Yachts (80FT+) Design. Brokerage. Accessories & Components Tent.

Bristol Yacht swim ladder. Bristol Yacht Components (BYC) has already introduced their lightweight collapsible boarding stair, but now they bring to market a new product: the Bristol swim ladder. Like the boarding stairs, this swim ladder is an all-carbon fiber design with UV-resistant clear coat finish and marine-grade stainless steel hardware ...

Connecticut-based Bristol Yacht Components has introduced the new Bristol Swim Ladder, which features a streamlined design, all-carbon fiber construction and a UV-resistant, clear-coat gloss finish.Light enough to be deployed by one person, the ladders employ a single, center beam design that supports five platform steps and three hand rails.

Essex, Connecticut, USA -- Exclusive Yacht Sales, L.L.C., the parent company of Bristol Yacht Components, was recently assigned a U.S. Design Patent for the company's Bristol Boarding Stairs™. The patent, No. US D664,494 S, was issued on July 31, 2012.According to the company, Bristol Boarding Stairs blend innovative engineering, advanced carbon fiber technology, and marine-proven

Bristol Yacht Components located at 15 River Rd #15b, Wilton, CT 06897 - reviews, ratings, hours, phone number, directions, and more.

The Bristol Swim Ladder employs a center beam design that supports five platform steps and three handrails. Features include carbon fiber construction, a ... Bristol Yacht Components, Essex, Conn., (860) 883-4904. www.bristolyachtcomponents.com. June 2013 issue. Tags. terms: Print magazine June 2013 Bristol Yacht Components New Gear. Equipment ...

Bristol Yacht Components manufactures boarding stairs for yachts of all sizes and styles. Bristol Boarding Stairs are made from strong, lightweight carbon fiber. They blend innovative design, pleasing aesthetics, and advanced engineering to provide beautifully crafted access for both motor and sailing vessels. Discerning yacht owners, yacht ...

One example of C 3 's high-quality, serial production is ladders for docking yachts, produced for Bristol Yacht Components (Essex, CT, US). The yachts move up and down relative to the dock, so the stairs must articulate. Dunham explains, "After about nine stairs, you have to turn the step sideways or the disembarking passenger would end up ...

Bristol Yacht Components manufactures boarding stairs for yachts of all sizes and styles. Bristol Boarding Stairs are made from strong, lightweight carbon fiber. They blend innovative design, pleasing aesthetics, and advanced engineering to provide beautifully crafted access for both motor and sailing vessels. Discerning yacht owners, yacht builders, captains and crew will appreciate the fine ...

Because of that, rather than a broader discussion of Bristol Yachts, I will therefore focus on the 38.8 specifically and touch on the keel-centerboard a little. ... Some of that weight went into heavier interior components and truly lovely cabinetry. Some went into a heavy duty teak toe rail, cast bronze portlights, and stainless steel ...

The boats phenomenal light-air performance is delineated in the Performance Package supplied by the United States Yacht Racing Union. In a true wind of 6 knots, close-hauled (44.5 degrees), the Bristol 35.5C, with a 120% jib, should do 3.9 knots. The velocity made good will be 2.8 knots. Shed be heeled only 5.

The 39 was one of the first models built by Bristol Yachts, entering production in 1966. Beginning with 1972 models, the boat was rechristened the Bristol 40. The last Bristol 40 was built in 1986. If you like traditional yachts, you'll find the Bristol 40 appealing. The boat has the long overhangs, lovely sheerline, low freeboard, narrow ...

Bristol Yachts: Download Boat Record: Notes. Fin keel or keel/cb. Keel/CB- BU: 3.5', BD: 7.5'. Available as sloop, yawl or ketch. Tall sloop: I: 40.0' J: 12.58' P: 35.1' ... The LWL will increase as the yacht sinks into the water with the added weight of stores and equipment. BEAM: This is the greatest width of the hull and is often expressed ...

Bristol boats for sale on YachtWorld are available for an assortment of prices from $9,226 on the relatively more affordable end, with costs up to $223,622 for the more sophisticated, luxurious yachts. What Bristol model is the best? Some of the most widely-known Bristol models currently listed include: 40, 35.5, 45.5 Center Cockpit, 38.8 and 31.1.

In one year 172 Bristol 27's were built. There was also the Bristol 29 designed by Halsey Herreshoff, the Bristols 32 and 39 designed by Ted Hood, and Bristol 34 designed by John Alden Assoc.. Later 'second generation' models included the 31.1, 35.5, 41.1, 45.5, 47.7 and then larger custom boats. In total, 4400 Bristol Yachts were produced ...

In one year 172 Bristol 27's were built. There was also the Bristol 29 designed by Halsey Herreshoff, the Bristols 32 and 39 designed by Ted Hood, and Bristol 34 designed by John Alden Assoc.. Later 'second generation' models included the 31.1, 35.5, 41.1, 45.5, 47.7 and then larger custom boats. In total, 4400 Bristol Yachts were ...

Our company Bristol and International yacht Refinishing is the largest Refinishing Company / Marine Supply in Central America / Costa Rica, with 25 years of experience, we work on a variety of Yachts doing top to bottom remodeling, fiberglass, Paint, custom built parts , custom teak /carpentry work, full paint jobs , bottoms and repairs Interior and Exterior, we now offer, electrical ...

service details. Bristol Yacht Refinishing stands out from the competition with our expert team of craftsmen, dedication to quality and top of the line marine products and over 25 year of experience in the industry. We have worked around the world working on different projects and have the knowledge and team to get the job done. From bottom ...