You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

- Link to search page

- US: +1 (561) 833 4462

- US: +1 (206) 209-1920

- MC: +377 99 90 74 63

The Top 10 Best Yacht Builders In The World

Here is our list of the best yacht builders on earth. Deciding which shipyard will build your luxury yacht is a complex and deeply personal choice, depending on many factors including the level of customization you want, your budget, the location of the shipyard, and the ‘feel’ you get for the yard’s vision and people.

Our list of the best yacht builders is naturally subjective and will not feature every well-known brand. Our short selection includes a range of shipyards, from manufacturers of the some of the most iconic custom-built superyachts to hugely popular production yacht builders.

Here are the best yacht builders on earth, sorted by region.

Usa – best yacht builders.

Westport is one of the dominant players in the American yacht-building market, with a hugely popular range of tri-deck and raised pilothouse motoryachts built from composite materials. Their models range from from the 112′ to 164′ (34m to 50m) series, allowing the yacht owner to customize the interior layout without the high cost and long timescale of fully-custom construction. As the largest American yacht building company in operation, Westport has a proud history of high quality yacht manufacturing dating back to 1964, with over 100 superyachts and over 170 fishing vessels launched from their Pacific Northwest Shipyard. Westport yachts are extremely popular in the US brokerage and charter market and have a reputation for holding their value well. View current Westport yachts for sale .

Christensen Yachts prides itself on the construction of American-built custom and semi-custom superyachts from fiberglass, including well known yachts M/Y CASINO ROYALE, M/Y SILVER LINING and award-winning M/Y ODESSA. Founded by superyacht owners, Christensen has a loyal following of yacht owners, many of whom are repeat customers. Currently producing yachts at its Vancouver, WA yard between 100’ to 165’ (35m to 50m) in length, Christensen was bought out in 2015 and is in the process of building America’s largest superyacht facility in Tennessee, which will construct vessels up to 70m. View current Christensen yachts for sale .

Northern Europe – Best Yacht Builders

German superyacht builder Lurssen is the builder of the largest superyacht in existence, the 590’ (180m) M/Y AZZAM, which was completed in an astonishingly quick three years. Known for superb build quality and large projects across its superyacht, naval vessel, as well as its’ yacht refit and management divisions, Lurssen is a family-run shipyard with a prestigious yacht building heritage spanning back to 1875, when it constructed the first ever motoryacht. Lurssen is the builder of 5 of the top 10 largest yachts in the world. View current Lurssen yachts for sale.

Feadship, Netherlands: For some yacht owners, the only name worth knowing is Feadship. This prestigious brand is synonymous with Dutch superyacht quality, and has a legion of steadfast and loyal fans. Dating back to 1849, Feadship creates fully custom yachts from a ‘blank slate’ beginning, priding themselves on creating supremely unique, innovative yachts that stand the test of time. There are 450 bespoke yachts currently afloat in the Feadship fleet, including M/Y HASNA, a 239’ (73m) with a revolutionary layout. Read more on Dutch yacht builders . View current Feadship yachts for sale .

Amels’ vast and high-tech superyacht facility is the largest in the Netherlands, producing iconic, high-value yachts up to 330’ (100m), including their 2017 flagship yacht, 272’ (83m) M/Y HERE COMES THE SUN. Amels offer a fully custom yacht building service, as well as their exceedingly popular Limited Edition Series, whereby the yacht owner retains control over interior and exterior design but the yacht is built on a proven platform, thereby slashing the build time. Amels also builds support yachts through their parent company, DAMEN, a heavyweight in global shipbuilding. View current Amels yachts for sale .

Dutch yacht builder Heesen is known for its aluminum and steel superyachts and innovative use of technology, as seen in the revolutionary fast displacement hull form first seen in the multi-award winning M/Y GALACTICA STAR, and the hybrid propulsion utilized in the 2017 launch of M/Y HOME. With a fleet of over 170 yachts launched since inception in 1978, Heesen is known for pushing the boundaries of what is possible in superyacht design and engineering. Heesen builds motoryachts between 100’ to 265’ (30m to 80m) in length at its Oss shipyard. View current Heesen yachts for sale .

Now owned by Lurssen, Blohm + Voss is a yachting powerhouse in its own right, constructing magnificent large superyachts including the iconic MOTOR YACHT A and 531’ (162m) M/Y ECLIPSE, currently the third-largest yacht in the world. The vast Blohm +Voss facility in Hamburg, Germany creates striking custom motoryachts and sailing yachts. View current Blohm +Voss yachts for sale.

Mediterranean – Best Yacht Builders

Benetti is a powerhouse of luxury yacht building, with a very healthy order list and a boat- building pedigree stretching back to 1873. Since 1960, Benetti has been constructing superyachts in Italy, including iconic yachts MY KINGDOM in 1980, then the largest yacht in the world at 280’ (85m), right through to recent launches such as the award-winning M/Y 11.11. Benetti is part of the Azimut-Benetti Group, the largest producer of luxury yachts in the world, building semi-custom and fully custom yachts between 100′ and 330′ (30m and 100m) long. Known for their Italian style and long history of yacht construction, Benetti has a loyal following of yacht owners who return to the yard each time they upgrade. View current Benetti yachts for sale .

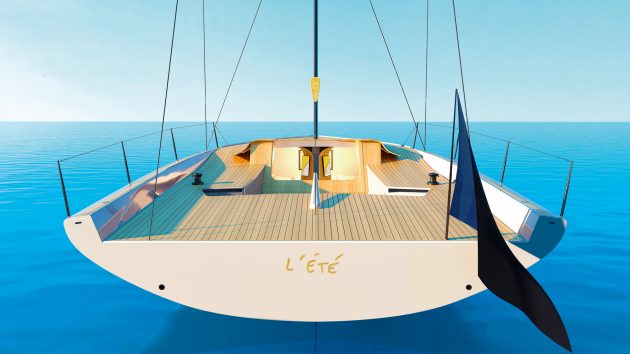

The creators of one of the most well-known yachts on the planet, S/Y MALTESE FALCON, Perini Navi enjoys a superb reputation as a sailing superyacht builder, and also entered the large motoryacht market in 2007 under its Pichiotti brand. Perini Navi yachts are known for their superyacht luxuries and interior volume, as well as the technically brilliant sailing systems that allow these large yachts to be operated by a small crew. Perini Navi dominates the sailing superyacht market with its range from 130’ to 200’(40m to 60m), constructed at their three shipyards in Viareggio, La Spezia in Italy and also in Istanbul. View current Perini Navi yachts for sale .

UK – Best Yacht Builders

Sunseeker is one of the most instantly recognizable names in the yachting world, building performance luxury yachts known for their speed and sleek looks. Once better known for their smaller sport yachts, Sunseeker is now a major player in the superyacht market, with customizable yacht models from 75′ to 155′, as well as constructing the Predator range with a top speed of 45 knots. Built and engineered in Dorset, UK, Sunseeker is Britain’s most famous luxury yacht builder, creating the hand-finished yachts regularly featured on James Bond films. View current Sunseeker yachts for sale .

Worth Avenue Yachts has extensive experience with each of these yacht brands. To find out more about the relative advantages of these shipyards or the other high-quality shipyards that we recommend, please contact us for an expert discussion.

Our knowledge & expertise.

A smart investment

Yacht construction & build.

With an experienced luxury yacht construction team comprised of former superyacht captains, engineers, and project management specialists, Moran Yacht & Ship has successfully negotiated, managed, and completed over $3 billion in new yacht-build projects. This incredible statistic is unmatched by any other brokerage company in the world.

- Luxury Yacht Construction

- Yachts Under Construction

- Completed Custom Yachts

Luxury Yacht Builders

- Contact Build Team

Why build with Moran Yacht & Ship?

Over the past 36 years, Moran’s yacht construction management team has been actively involved in successfully building over 60 of the finest quality new superyacht construction projects globally. Contact our new build project management team today to learn how we can help you build your next custom luxury yacht in partnership with the leading megayacht builders in the industry.

Discover how our yacht build process is different

Before the keel is even laid, our yacht project management team compiles an all-encompassing marine specification. We then negotiate a comprehensive yacht-building contract that protects our clients from delays and additional costs. We assemble an experienced yacht build team that includes only the best naval architects, interior and exterior designers, and project managers to bring your dream yacht to life.

Unlike many of our competitors, who disappear as soon as the yacht build contract is signed, our accomplished team will remain in place through final delivery to ensure a smooth yacht construction process and complete satisfaction. As a further courtesy to our clients, we remain with the vessel in a yacht management capacity to take care of any warranty items and ensure hassle-free day-to-day operations.

Completed Custom Yacht Construction Projects

BLACK PEARL

LADY KATHRYN V

QUATTROELLE

View ALL Completed Projects

Our results speak for themselves.

Whether you are looking to build a semi-custom motor yacht or build a custom superyacht, you can be certain that the new yacht construction team at Moran Yacht & Ship has the experience, knowledge, and capability to deliver the boat build of your dreams. Our experience ensures that you will take delivery of your vessel on time, within budget, and to the highest quality standards.

Yachts Currently Under Construction

PROJECT 146

View MORE Projects under construction

Choosing the right yacht builder and shipyard is imperative for a successful new yacht construction project. Learn more about some of the builders our yacht project management team works with and recommends.

Yacht Construction FAQs

What support will moran yacht & ship offer me during my yacht construction.

The experts and brokers at Moran Yacht & Ship have been in the industry for a long time and oversee many superyacht construction projects. Their expertise will support you at every stage of the new build process, ensuring your exact requirements are met. This includes:

- Informed selection of builder and shipyard

- Choice of interior and exterior designer

- Development and negotiation of the technical specification

- Negotiation of the build contract and price

- Project management throughout the build process

What does it cost to build a yacht?

The cost of building a yacht from scratch is based on multiple factors, including the size of the vessel, materials used, the complexity of the design, technology, propulsion systems, interior design features, onboard amenities, and the shipyard and designers used. Expect building a luxury boat to cost anywhere from $2 million to more than $300 million. Working with an experienced new build project management team, such as the experts at Moran Yacht & Ship, offers a cost-effective solution by ensuring builds remain within budget.

What are the benefits of building a yacht as opposed to buying a used yacht?

There are multiple benefits to building a yacht as opposed to buying a pre-owned yacht. When you build your own yacht, you enjoy the benefits of a fully customized vessel to meet your precise requirements, from its naval architecture and size to its cruising capabilities, layout, onboard technology, amenities, and interior design. A custom yacht will be tailored to suit your lifestyle and desired experiences.

Also, when you build your yacht, you won’t have to worry about pre-existing conditions. A new build yacht will come fully warranted, providing protection from future mechanical repairs and providing complete peace of mind.

Finally, Moran Yacht & Ship ensures that building a yacht is indulgently fun. You will have the opportunity to collaborate with a team of highly experienced boat-building professionals to create something truly extraordinary, from sketch board to on the water. Nothing matches the thrill of building your own yacht with even the smallest details tailored to your precise requirements. Indeed, a custom yacht offers the ultimate lifestyle purchase.

What are the pedigree shipyards that Moran has built with?

- Lurssen Since 1875, the northern German shipyard has produced some of the finest vessels on the superyacht market. This pedigree shipyard is known for innovating and utilizing cutting-edge technology. Lurssen continually breaks records, including developing both the longest superyacht in the world (AZZAM) and the biggest luxury superyacht in the world (DILBAR).

- Amels This Dutch shipyard officially entered the yachting sphere with the superyacht KATALINA, now named LADY GEORGINA, in 1982. The luxury boat builder specializes in motor boats, constructing both full custom as well as their highly sought-after semi-custom Limited Editions yacht series.

- Oceanco Oceanco is a pedigree boat builder and industry pioneer based in the Netherlands. The shipbuilder is renowned for building award-winning custom vessels up to 200 meters, both motor yachts and sailing vessels. The Dutch shipyard specializes in building innovative, high-quality superyachts that push the boundaries of shipbuilding.

- Feadship Also among the world’s most notable superyacht manufacturers is Feadship, a full custom motor yacht builder known for its uncompromising pursuit of perfection. The pedigree shipbuilder is located in Holland and boasts a long history stretching back to 1949.

Moran Yacht & Ship boasts strong relationships with the world’s leading shipyards and has project managed some of the world’s most luxurious custom superyachts. Contact us today if you want to build a luxury boat.

What countries are known to have the best shipyards?

European countries, including the Netherlands, Italy, France, and Germany, dominate when it comes to the best shipyards, thanks to their rich maritime heritage, skilled craftsmanship, and use of exceptionally high-quality materials.

What are the current waiting times to build a yacht with the best shipyards?

Overall, the more prestigious the shipyard, the longer the waiting time will be. Current waiting times for some of the most prestigious builders are around 4 to 5 years.

How long does it take to build a yacht?

The build time for a yacht can vary significantly depending on the project’s size, specifications, and complexity. Generally, superyacht construction times at pedigree shipyards range from 36 to 39 months.

Our new construction team is known for delivering our client’s projects on time and within budget.

What are mega yacht hulls made from?

Megayacht hulls are typically made from fiberglass, aluminum, or steel, and the choice of material will depend on the budget, yacht design, and how the owner wishes the vessel to perform.

A fiberglass hull is known for its excellent sea-keeping capabilities and ease of maintenance.

Aluminum offers excellent strength and durability. As a relatively lightweight material, it also provides better fuel economy and enables a yacht to reach higher speeds.

Steel is an exceptionally strong and durable material with high resistance to abrasion, making it popular with ocean-cruising yachts, especially expedition vessels. However, it is heavier than fiberglass or aluminum, making it less popular with owners wishing to build a yacht where speed is a priority.

What makes a boat considered a yacht?

Overall, there is no standardized definition of what makes a yacht. Mostly, the term yacht applies to vessels over 24 meters, where regulations for ownership change as well. The term yacht can equally define a motor boat or sailing vessel. Additionally, terms like superyacht, megayacht, or gigayacht are often used to describe the most luxurious and largest ocean-going vessels.

Do I have to pay VAT on a new yacht?

As a moveable asset, whether you have to pay VAT – Value Added Tax – can be complex. Generally speaking, whether you have to pay VAT will depend on the country the owner is acquiring the yacht from and their country of residence. The VAT may also depend on the intended use of the vessel. Every country has different VAT rules and regulations. It is always a good idea to consult with a local tax professional with expert knowledge of the yachting industry to mitigate any potential tax liabilities.

What are financing options for yacht construction?

Building a new luxury boat can be an expensive endeavor and is a significant investment. Various financing options are available to those interested in purchasing or building a yacht. Financing typically involves one of three different solutions:

- Portfolio loans

- Private lenders

Bank loans are a popular option for financing a yacht construction. Many banks offer boat loans, which are similar to auto loans in terms of loan structure and required collateral.

Portfolio loans have become more popular for financing new construction projects. A number of institutions offer these and often have very favorable rates.

Private lenders also offer funding for boat construction. These lenders typically offer more lenient terms compared to banks. However, interest rates can be higher, and a larger down payment is often required.

How much does it cost to run a yacht per year?

The cost of running a yacht depends on many factors, including:

- Maintenance needs : they will also grow with the age of the yacht

- Size : the larger the yacht, the more crew is required

- Time spent cruising : fuel expenses increase with the cruising range

- Insurance costs

- Location : dockage and mooring fees will vary

Overall, a rule of thumb is that luxury yachts cost around 10% of their purchase price per year. This percentage is typically reduced slightly as the size of the boat increases.

Contact our New Yacht Construction Team

Are you considering building a new yacht? Contact our team today to learn how we will set you up for success.

WE BUILD SMART YACHTS FOR SMART OWNERS

At Dynamiq, we believe in a smarter way to build yachts. We believe in intelligent buyers and next-generation yachts that are efficient, easy to order and effortless to customize. We believe in the latest technologies, logical innovations and unique collaborations. We believe in the winning, value for money formula of yachts that are engineered in the Netherlands, designed in Monaco and crafted in Turkey. So don’t think too hard. Live smart. Be Dynamiq.

YOUR SPECIAL PLAYGROUND FOR YACHT BUILDS FROM 35 to 65 METERS

The shipyard.

The construction of Dynamiq yachts is carried out in the Antalya Free Zone, Turkey, which is a government-protected area that benefits from a special tax regime lowering costs and hosts a cluster of high profile shipyards from both Turkey and the Netherlands. Dynamiq occupies the most modern and newest facility in the Free Zone, with 10,000 m 2 covered space and access to a 2,000 ton syncrolift for safe and easy launching. The sheds are well fitted out for building the full range of Dynamiq superyachts up to 65 meters in length. Various powertrain options are available including hybrid or diesel-electric technology.

The works are organized with international subcontractors from Germany, Austria and Italy, who team up with the best local craftsmen to achieve a level of quality in line with North European standards. Dynamiq has in-house interior, teak and stainless steel production to ensure that the end product finish is absolutely perfect and minimize the risks of delays. The shipyard working environment is carefully managed and strict quality control standards are maintained by both the Dynamiq team and external surveyors from Europe. Dynamiq organized dedicated modern office spaces to welcome owner's representatives and crew members.

Designed in MONACO. ENGINEERED IN THE NETHERLANDS. CRAFTED IN TURKEY.

The Dynamiq range is a product of leading European technology and craftsmanship. This unique international approach has created an innovative superyacht of the highest quality born from a collaboration of the world’s top superyacht design and construction experts.

GRAN TOURISMO TRANSATLANTIC

- LOA 35.5 metres

- Max speed 23 knots

- Starting at 17,250,000 €

- LOA 41 metres

- Max speed 21 knots

- Starting at 21,000,000 €

- LOA 50 metres

- Max speed 16/21 knots

- Starting at 29,500,000€

- LOA 52 metres

- Max speed 19 / 23 knots

- Starting at 31,500,000 €

- LOA 40 metres

- Max speed 14 knots

- Starting at 24,000,000 €

- LOA 45.5 metres

- Starting at 28,750,000 €

G 500 Hybrid

- LOA 50 metres

- Max speed 16 knots

- Starting at 30,900,000 €

- LOA 55.7 metres

- Starting at 32,500,000 €

WHY DYNAMIQ?

Forward thinking design, innovative naval architecture, highest engineering standards, top-quality steel & aluminium construction, ocean-going range, smart pricing.

Dynamiq's unique exteriors look impressive and fresh and express the sporty, chic soul of our yachts. They not only look great, but also perform at the top of their class and lend owners a sense of exclusivity and pride.

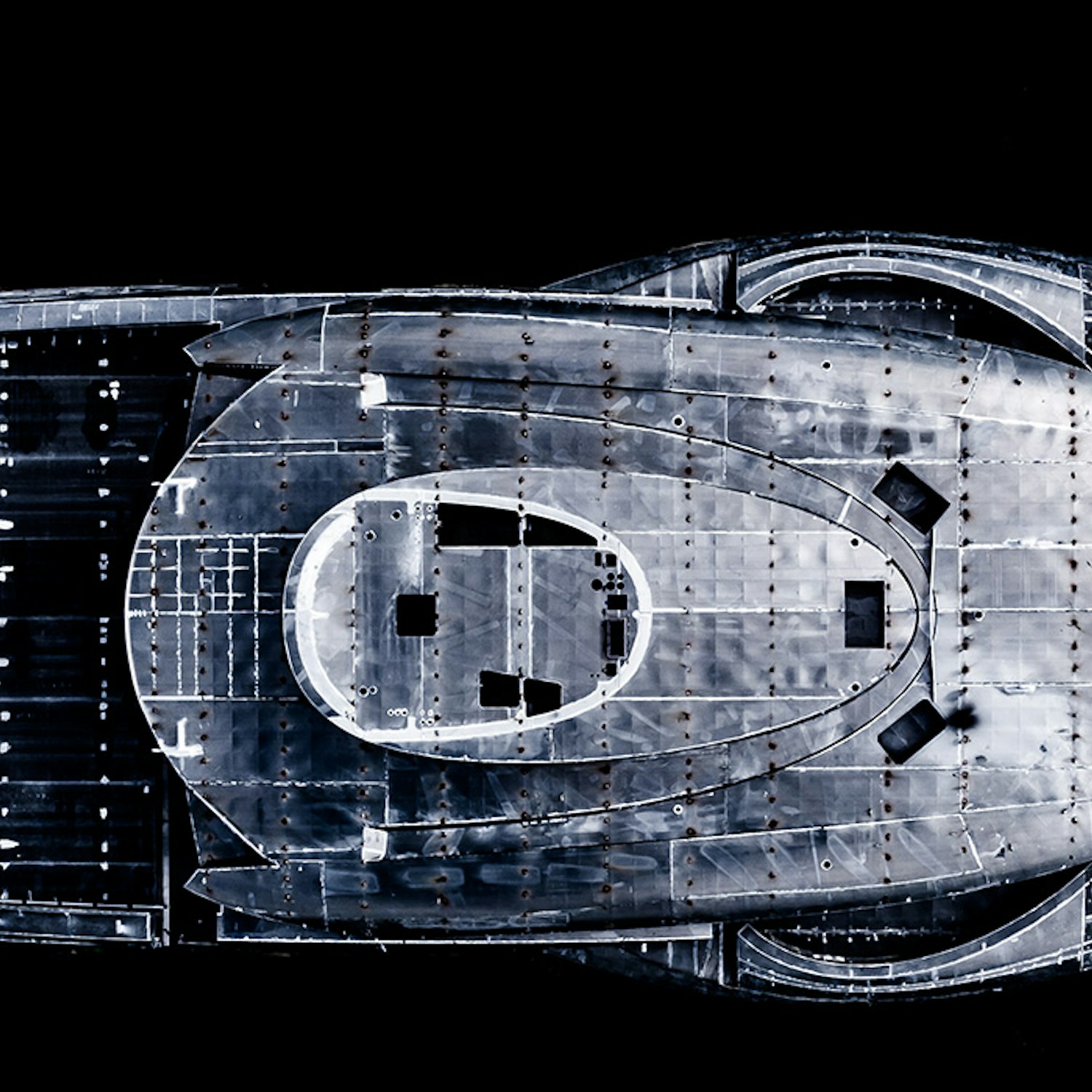

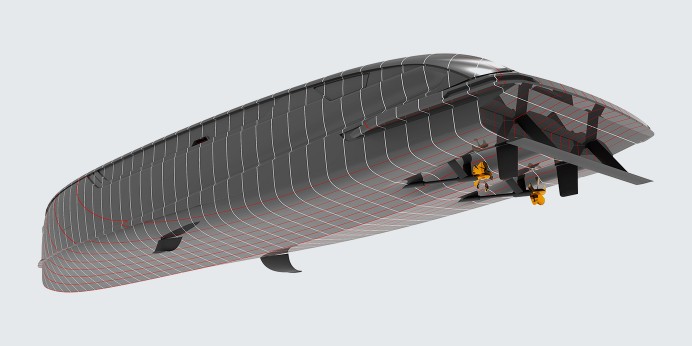

Dynamiq’s high efficiency is based on innovative technologies in modern naval architecture: fast displacement hull lines, the Hull Vane under the stern, and Sleipner curved fin stabilizers. Completely drawn by leading naval architects in the Netherlands, all Dynamiq yachts feature a round-bilge shape for remarkably low resistance and low fuel consumption, while providing seaworthiness and comfort with long waterline length and low centre of gravity.

Each Dynamiq yacht is by definition safe, comfortable and environmentally friendly in accordance with the strictest RINA and BV Commercial Class standards, prestigious Comfort and Green Star Plus notations, Large Yacht Code 4 (LY4) compliancy and manning standards. This not only makes our vessels ultra-safe and almost silent, but also means they can be chartered to offset the cost of ownership.

Only certified marine-grade steel, aluminium and Sealium are used for Dynamiq hulls and superstructures. In comparison with composite hulls, they are much quieter, easier to repair and have higher trade-in value due to the fact that they have a very long service life.

Dynamiq yachts are designed with an ocean-going capability in mind, which means owners have the opportunity to enjoy multiple seasons during the year (say Mediterranean and Caribbean) and visit remote locations with no re-fueling infrastructure. Equipped with high-capacity marine fridges and freezers, cold garbage stores, separate laundry facilities, plenty of storage space, generous fresh water tanks and powerful water-makers, Dynamiq yachts provide autonomy at sea in complete comfort.

Combining Dutch engineering with production facilities in the one of the biggest Turkish shipbuilding hubs of Antalya Free Zone means Dynamiq can offer North European standards and quality craftsmanship at significantly reduced prices. Being pioneers in the superyacht industry, Dynamiq also has an Online Configurator where clients can customize their yachts in a few clicks and see in real time how the price and delivery times vary.

SALES REPRESENTATIVES

- INTERNATIONAL

- Maria Dobroserdova

- Dynamiq Sales Director

- M: +33 617 07 93 26 [email protected]

- Language: English, French, Russian Location: Monaco

- Türkiye

- CANDAŞ BALCI

- BLC Yachts Brand ambassador

- M: +90 543 373 92 07 [email protected]

- Language: Turkish & English Location: Türkiye

- Emi Okamoto

- Japan Yacht Management Brand ambassador

- M: +81 (0) 80 6791 1048 [email protected]

- Language: Japanese & English Location: Japan

- Germany, Austria and Switzerland

- Lukas Stratmann

- Ocean Independence Brand ambassador

- M: +49 151 1211 2887 [email protected]

- Language: German & English Location: Germany

Select your Language

- KM Yachtbuilders

- The Shipyard

- - Aluminium

- - The People of KMY

- - Custom Yacht Builders

- - Design Process

- - Building Process

- The Services

- - Brokerage

- - Painting Service

- - Customer Care

- - Build Your Own Yacht

- - Bestevaer

- - Sailing Yachts

- - Motor Yachts

- - Visit the Shipyard

- - Partnerships

- - Careers (Dutch)

World's finest explorer yachts.

We build dreams. With over 30 years of expertise, we craft custom aluminum explorer yachts of unparalleled quality, tailored for the most extreme destinations. Specialized in high-latitude expeditions.

Is your yacht in need of maintenance, repairs or a large refit? We’re happy to help you with it. We not only work on aluminium yachts but also on steel, polyester or even wooden yachts.

Designed by one of the world’s most legendary sailors as his private yacht. Brought to you by KM Yachtbuilders, the leading builder of aluminium expedition yachts up to 100ft.

We are KM Yachtbuilders

We build aluminium yachts. Since 1998, KM Yachtbuilders has pioneered innovative and no-nonsense aluminum yacht construction, prioritizing safety and adventure. Starting out with three people and about as many yachts. A few decades later we are a team of 45 with more than 100 builds under our belt and our yachts are sailing the seven seas from pole to pole.

Visit us during the Hiswa in Water Boat Show 2024!

Click HERE to schedule your personal viewing. Explore the latest innovations in yacht building and discover our exquisite range of custom-built yachts. Whether you’re a seasoned sailor or […]

Choose your destination, comfortably go wherever you want to go.

Fleet highlights, 2017 aluminium buster xxl, bestevaer 42, bestevaer 50 ‘volans’, bestevaer 53 ‘surminski’, bestevaer 53 ‘tethys’, german frers 105 bolero, allures 39.9 imagine, bestevaer 41 josephine ii, altena 53 happy hours, ovni 400 a plus, bestevaer 63 m/y, bestevaer 36 ‘bv3’, hoek 65 weatherly, bestevaer 73 christopher, bestevaer 53 xaos, ovni 43 sanderling, pelagic 77 ‘amundsen’, bestevaer 54 ‘micmac’ (prev. canada), bestevaer 56 panta rhei, bestevaer 53 m/y #3, bestevaer 62 luskentyre, bestevaer 53 my still, bestevaer 45 lionne, bestevaer 53 m/y bryndis, km custom yachts.

A custom built yacht is a journey in itself. Every customer comes with their own set of demands that depend on the purpose of the boat. Decades of experience, teamwork and a profound love of our craft help us to always come up with solutions for the most challenging demands.

Bestevaer yachts

Bestevaer s/y, bestevaer m/y, custom bestevaer 1/1, the world's finest explorer yachts., become part of the km family.

Our team is always ready to assist our yacht owners with advice and assistance in the event of contingencies.

Explore Bestevaer yachts

Designed by one of the world’s most legendary sailors as his private yacht. Brought to you by KM Yachtbuilders.

- Frank Magazine

- Denison History

- Virtual Tours

- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Lekker Boats

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Ocean Alexander Yachts

- Offshore Yachts

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

- Pershing Yachts

- Prestige Yachts

- Princess Yachts

- Pursuit Yachts

- Riva Yachts

- Riviera Yachts

- Sabre Downeast

- San Lorenzo Yachts

- Sea Ray Boats

- SeaVee Central Consoles

- Selene Trawlers

- Scout Yachts

- Sunseeker Yachts

- Tiara Yachts

- Trinity Superyachts

- Viking Yachts

- Westport Yachts

Building A Custom Superyacht [Complete Newbuild Guide]

![yacht building Building A Custom Superyacht [Complete Newbuild Guide]](https://cdn.denisonyachtsales.com/wp-content/uploads/2019/07/Building-A-Custom-Superyacht.jpg)

July 25, 2019 11:40 am

The process of building a large yacht explained.

Placing an order for the build of a large yacht is no small undertaking. It is likely the result of a lifetime—perhaps even generations—of wealth building for such a purchase to become an option. When the time comes, how does the client start the process and where does he or she look for suitable partners? The maritime world is famously full of jargon, and the luxury yacht business is no different. Brokers , naval architects, interior designers, class societies, custom yachts, production yachts, flag states, owner’s supply, surveyors, shipyards, subcontractors, builder’s risk insurance , project managers, tank testing . . . you catch my drift.

Thought-through decisions and complicated contracts should certainly be anticipated, but as a wise man once told me about yachting, “At the end of the day, it’s all about cocktails on the beach.” While the dream of being on the water waits at the end of a newbuild process, building a yacht should be an enjoyable and rewarding process in itself.

- Newbuild Process Overview

- Latest Trends In Yachting

- Newbuild Partnerships

- Flexibility

- Project Management

- Newbuild Projects For Sale

- What Sets One Builder Apart from Another?

- What Sets A Brand Apart?

NEWBUILD PROCESS

“Production” Yachts tend to be in the smaller range and the process will likely be simpler than for a custom build. With a finished product already in inventory and available, only minor interior design elements need to be added per the client’s choice. A number of yacht builders will begin building larger yachts in anticipation of finding a buyer later, offering “semi-custom” as an option for elements of the interior layout and design.

For the custom build, the process will look something like this:

Vision > Design > Contract > Build > Sea Trial > Delivery > Cocktails on the Beach

The above is an intense simplification. Each stage involves multiple levels of experts and support staff. The client will want to surround him or herself with qualified attorneys, technical advisors, and translators of the jargon. One other important element to mention is that the design and build contract cost will not be the only outlay required to reach the endpoint. Custom yacht contracts mostly do not include items known as “Owner’s Supply,” i.e. tenders and water toys, audio-visual/entertainment systems, loose furniture, tableware, and more. Each of these will need to be procured, stored, insured, and integrated into the yacht itself as part of the process.

LATEST TRENDS

Step one, “Vision,” allows almost anything to be conceived and delivered in a yacht. There are plenty of “concept designs” available on the internet to offer the client inspiration for their vision, but we have seen a few trends in recent years. The “plumb bow,” the explorer yacht, hybrid propulsion, podded propulsion, as well as attention to environmental impact elements of the design and subsequent operations are all topics which have received attention in the industry press.

PARTNERSHIPS

As with any high-value undertaking, a large yacht construction project will require numerous partnerships and you may be asking yourself, “Who is involved with a custom yacht build process?” With the client at the top, some or all of the following will be necessary for a successful and enjoyable project experience:

A yacht broker , to advise the client on availability and the suitable market for construction and opening budget concepts. A naval architect for concept design. An engineer for detailed design. An interior designer. Attorneys for contract review, tax advice, etc. An insurance broker . A yacht builder , who may also provide some or all of the naval architecture, engineering, and even interior design services. Flag State , to provide surveyors with approval of safety code compliance. Classification Society, a third-party service assuring the quality of construction. Owner’s Project Manager , to record and represent the client’s interests across the entire project. (Depending on the size of the yacht, this may be one person or a team.) Yacht crew. (Depending on the size and complexity of the yacht, it may be wise to start bringing a crew into the project 6-12 months from completion.) Owner’s supply vendors , for audio-visual/entertainment systems, tenders, spares, and consumable supplies all needed to be managed and integrated into the final delivery.

FLEXIBILITY

The best plans are flexible and organized carefully so that changes or delays do not derail a project entirely. With this in mind, each partnership must be equally flexible throughout the project since an owner’s design needs, the yacht’s delivery schedules, and compliance requirements often change.

PROJECT MANAGEMENT

The process of building a large yacht is a long-term commitment and a major investment. A prospective client may consider hiring a project manager to assist with fielding the complexities at hand, protecting the client’s interests in the process and enabling the finished dream to be delivered on time and on budget. For a “simple” project, the project manager may be one person attending the yard on an occasional basis, but for larger builds, expect to see numerous staff on the project management team—some full time and others with short-term specialties needed during particular phases of the build.

NEWBUILD PROJECTS FOR SALE

Denison Yachting represents a number of builders in various regions of the United States with dealerships for Hatteras and Horizon, both of which typically build production or semi-custom yachts. Additionally, Denison is currently offering a number of new construction projects from yards Rosetti, Numarine , and Van der Valk , who all offer fully custom and semi-custom projects. Each year, we commit to visiting various yards in Italy , Germany , and The Netherlands to stay up to date on project availability and maintain relationships with the world’s top yacht builders.

Yacht brokerage houses often show newbuilds for sale. This may be a case where a builder has a design that they are promoting to the market, or maybe have even started construction without a specific client under contract. In some cases, clients or builders will start new construction as a speculative investment intending to sell the contract to a third party.

WHATS SETS ONE BUILDER APART FROM ANOTHER?

Boat International’s Builder Directory includes 1,805 separate entries, so the choices are broad. Builders can be found in Italy, Germany, the Netherlands, the UK, the USA, Turkey, China, Taiwan, Australia, and beyond. Some builders may specialize in a particular material, i.e. GRP, aluminum, or steel, and others may limit the size, the numbers, or the design choices (custom/production.) A client may use any of these to narrow down the selection, but the real distinction between builders will be the manner in which they treat the client. If the client is made welcome in the builder’s facility throughout the process, that builder will more than likely succeed. If the builder is transparent in their process, then they will succeed. If a builder says “yes” to every client request but fails to deliver, then they will likely fail.

Once a client has a particular style of yacht in mind, the selection of suitable builders will narrow down even further and the client’s broker should assist that process with their knowledge of the market. Then the client may consider asking candidate yards to suggest design concepts, then begin the evaluation and decision process. If using an independent naval architect to produce a concept, they may suggest suitable builders for the vision.

WHAT SETS A BRAND APART?

There are innumerable brokerages willing to sell a client a newbuild, and just as many builders who would likely be willing to deal direct. Do all of those companies have the depth of experience, integrity, expertise, and background that is needed to assist a client seeking to embark on such a high-value and complex project? Has that broker taken the time to learn the market options available? Do they have the skills necessary to listen and advise for the client’s benefit rather than their own? Denison has the build and brokerage experience matched with the knowledge and integrity required to take a client to the next level of their yachting dream.

Latest News

NEWS | August 23, 2024

Cocktails & canapés at 37th america’s cup [s/y seaquell].

Cocktails & Canapés at 37th America’s Cup [S/Y SEAQUELL] Thursday, August 29th | 19:00-21:00 Denison Yachting cordially invites you to an evening of cocktails and canapés aboard the Sailing Yacht SEAQUELL during the 37th America’s Cup Round Robins at Port Forum. Enjoy a relaxed gathering on board, set against

Newport International Boat Show [Brokerage Boats On Display]

Newport International Boat Show [Brokerage Boats On Display] Thursday-Sunday | September 12-15, 2024 Denison invites you to view a number of available brokerage boats at the 2024 Newport International Boat Show. The Newport International Boat Show, set for September 12-15, 2024, in Newport, Rhode Island, is one of

NEWS | August 19, 2024

85′ azimut 2006 sold by florent moranzoni [eva].

85′ Azimut 2006 Sold by Florent Moranzoni [EVA] EVA, an 85′ (26.82m) Azimut built in 2006, was sold by Florent Moranzoni, who represented the Seller. Special thanks to James von Eiberg of Bluebnc, who represented the Buyer. EVA can accommodate ten guests in four comfortable cabins, including a

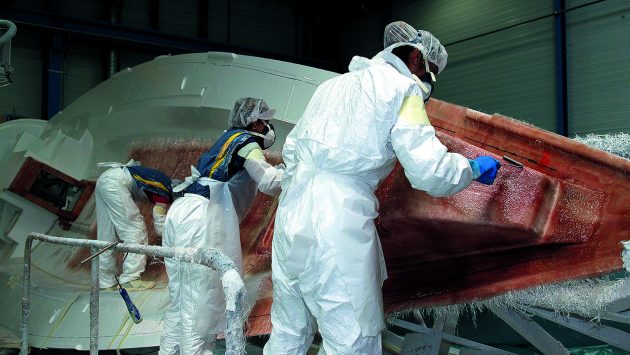

Building a Yacht: Top Things to Know About the Yacht-building ProcessOwning a yacht and having the freedom to explore our beautiful planet by boat is a dream shared by many. But building a yacht is a long and complex process. Should you be one of the fortunate ocean explorers who will get the opportunity to have your semi custom yacht built from scratch, you will undoubtedly require the services of an experienced and knowledgeable boat builder. Knysna Yacht Company is a boutique yacht-building company based in the picturesque coastal town of Knysna on South Africa's world-famous Garden Route, and crafting beautiful, artisan-made semi custom yachts for clients around the globe is what we do best. Having your yacht designed and built by a professional, acclaimed yacht builder like KYC will not only see you sailing off in a unique boat that was built to the highest standards. It will also ensure that you are a pivotal part of your yacht's design and construction process, right from the very outset. While KYC builds your yacht, your input will not only be valued, it will be sought out and encouraged, with your particular tastes and preferences incorporated in every aspect of your boat's construction. Continuous consultation and communication with the KYC team of expert yacht builders will see you taking to the seas in a boat that not only complements your personal style, but one that can truly be your home on the high seas. Read on as we take a closer look at the various aspects of the semi custom yacht building process. #1: What are the trademarks of a semi custom yacht?When you first start to do your yacht-buying research, you'll no doubt come across various types of yachts available for purchase. Most of these will be standard, production yachts. With a production yacht, what you see is truly what you get. There are virtually zero customizations that you can make to the layout or interior of an off-the-shelf production yacht, A semi custom yacht, however, will afford you much more opportunity to add all those little touches that will make your boat a true extension of your personal style and tastes. Even though semi custom yachts are built on a standard hull, when it comes to trims and finishes, appliances and the interior layout, that is all up to you.7The planning and design of a semi custom yacht can be compared to working with a home builder. Many larger home building companies have several base floor plans to select from, with the selection of cabinets, finishes, layout, and other details entirely up to the owner. It's the same with the design of a semi custom yacht.  #2: The advantages of a semi custom yachtYou might be wondering if a semi custom yacht is a better option than a standard production yacht. Buying a production yacht may save you money, but going for the cheapest option is not always the best choice. There are clear advantages to having your own semi custom yacht built by professional yacht builders. One of those advantages is that you will personally be involved in the entire process of your yacht's construction. A semi custom yacht build takes around 12 months to complete, allowing you ample time to really get stuck into the various design, building and finishing aspects of your boat. In addition, you will almost certainly be cementing a long-lasting relationship with the dedicated team that is building your boat. Should you choose KYC as your yacht builder, this relationship will continue long after your boat's build is complete. With a semi custom yacht, the price may be higher than what you'd pay for a standard production yacht (although the costs of KYC's boutique semi custom yachts compare very well with some new production yachts on the market). But, if you choose to go for a semi custom yacht, you'll be getting much more than just a boat. You'll be setting sail in a vessel you can take immense pride in, because you would have played a central role in crafting your boat to your exact tastes and specifications. If you select KYC as your yacht builder, you can also look forward to the many benefits of becoming a member of the KYC family of yacht owners. This means you'll enjoy the support and expertise of an experienced team of yacht-building professionals for many years to come.  #3: Semi custom vs. production yachtThe advantages of having your own semi custom yacht built for you may be clear, but how do these boats compare to standard production yachts ? Well, one major difference is alterations. When you're having a semi custom yacht built, you can make changes as you go. With a standard production yacht, you are buying the boat pre-made. Alterations to a production yacht after the fact can cost a lot of money, and may not be that simple – or safe – to execute. Why would altering a production yacht post-sale be a safety risk? A production yacht's design and aesthetics may hide pre-existing flaws in the boat's construction. In itself, this could already pose potential safety risks. Making further changes or additions to a yacht that may already contain pre-existing design flaws would not be a wise course of action, and could be very dangerous indeed. If you're involved in every step of the build of your semi custom yacht, you will have the opportunity to closely inspect your boat at every stage of its construction. This is a valuable advantage that could potentially allow you to avoid safety issues and layout problems relating to your boat. #4: Building a semi custom yachtIf you choose to have yacht builders build your semi custom yacht from scratch, you'll be involved in every step of the process. For this reason, it will be in your interest to know as much as possible about your boat's building process. So, what is the actual process of building a semi custom yacht?  Building the hullThe first stage of the yacht-building process involves the "bones" of your yacht. During this stage, your yacht's hull and superstructure are made. Unless they have commissioned a completely custom yacht to be built from the ground up, boat owners typically aren't involved in the selection of their boat's hull. However, it is important to know what this process involves. Constructing a boat's hull is a process that takes four to six months to complete and takes place in a boat builder's aluminium or steel workshop. A steel yacht hull is extremely durable, but it will add a lot of weight to the overall weight of your boat. Steel is one of the most common hull-construction materials, as it can be constructed and maintained with low technology, and at a relatively low cost. Aluminium or alloy hulls are one of the better options available for hull construction, as they are so much lighter. These hulls offer the durability and longevity of steel hulls, but add only a fraction of the weight of a steel hull to your yacht. After your yacht's hull is complete, it will have to go through a rinsing and priming process before your boat will be ready for the next step in its construction: finishing. Finishing the yachtOnce your yacht's hull is complete, the second stage of your yacht's build can commence. This is the part where you'll start to see your boat "come to life". The finishing process of your yacht is made up of several stages, including:

Semi custom yachts are beautiful machines. And, under such a boat's surface, a lot goes on to keep that beautiful machine moving and functioning as a self-contained living unit on the water. A large network of wiring and systems will be expertly installed to keep your yacht running smoothly and safely.   Yacht systemsIt takes several systems for your new boat to run, including a navigation system, anchoring system, electrical system, propulsion system, air conditioning system, water systems, and more. Each of your yacht's systems requires an expert team possessing the necessary knowledge and expertise to install it correctly and efficiently. Some people set sail with a yacht engineer as part of their crew team, to keep everything running smoothly onboard. However, KYC offers all new Knysna yacht owners a complimentary, 2-week training period during which they are shown and taught everything they need to know in order to maintain their yacht's systems themselves. Gel coating & interior and exterior carpentryA yacht's gel-coating process is done with a resin that bonds with the fibreglass surfaces throughout your boat. Gel coating ensures no leaks and cracks on a yacht's surface, but it can also be applied to add more colour to your boat. Since most yacht hulls and exteriors are finished in fibreglass, gel coating becomes an extremely important part of the yacht-building process. After gel coating, the interior of the yacht receives a protective varnish. The yacht exterior is also gel-coated and waterproofed to prevent leaks and ensure the boat is completely sealed. Carpentry is also an essential component of your new yacht. Marine carpentry experts are required for both the interior carpentry (think bathroom cabinets, kitchen counters and seating), as well as the decks and other carpentry aspects on the boat's exterior.  Yacht builders and their teamsIf you select to have your yacht built by a big yacht-building company, a project manager will be appointed to oversee your yacht's construction, making sure the entire process runs smoothly. Project managers are typically the face of a boat-building company, and clients will deal with their boat's project manager as their point of contact throughout their yacht's construction process. Underneath the project manager, you'll likely have a team of engineers, systems installers, artisans, an interior designer, and a few legal team members. Should you choose to have your semi custom yacht built by KYC, you will be dealing directly with KYC’s owners. You will also have access to your under-construction yacht at all times, ensuring that the lines of communication remain open and that your needs are being met.  Selecting the right yacht builderIt's essential to choose the yacht builder best suited for your particular project. There are several questions you should ask yourself before selecting a company to build your yacht. First, you will have to decide on the type of vessel you want. Many boat builders specialise in certain types of boats. Knowing what type of boat you want will be the first step toward deciding which yacht builder is right for you. Next, you'll want to figure out how far you'll typically be sailing. This is known as your yacht's range. If you're only planning on doing shorter sailing trips, that will require a specific type of boat. If you want to sail out on the ocean for weeks or months at a time, that will require a different kind of boat entirely. Finally, ask yourself how long you're willing to wait for your new boat . This wait is known as your lead time. If you're okay with waiting 2-4 years for your yacht to be built, then you can consider selecting a fully custom yacht. Semi custom yachts, including KYC’s artisan-built Knysna 500SE and Knysna 550 yachts can be completed much faster. This will vary from builder to builder, but most semi custom yachts have a much shorter lead time than a fully custom boat that is built from scratch. Financing a semi custom yachtFinancing a boat that is yet to be built is notoriously difficult, with most banks and financial institutions only willing to provide loans for completed boats. At KYC, we offer clients a Yacht Construction Financing Option, allowing them full flexibility to pay off building costs over the boat's complete building timeframe.  Become a yacht owner fasterLet us answer your yacht-building questions! Read our blog article on yacht financing and learn more about KYC's unique Yacht Construction Financing Option.  Let us answer your yacht-building questionsThere are lots of points to consider when you're thinking of having a boat built. Our team of KYC yacht-building experts will help you navigate the yacht-building process to ensure that your journey towards ultimate freedom is smooth sailing every step of the way. Don't hesitate to send us a message at [email protected] and let us know how we can help.  Yacht Maintenance - Top Tips for Protecting Your InvestmentEssential things to know about boat insurance, top things to know about yacht solar power, get all the latest to your inbox, discovery awaits.  Yachting Monthly

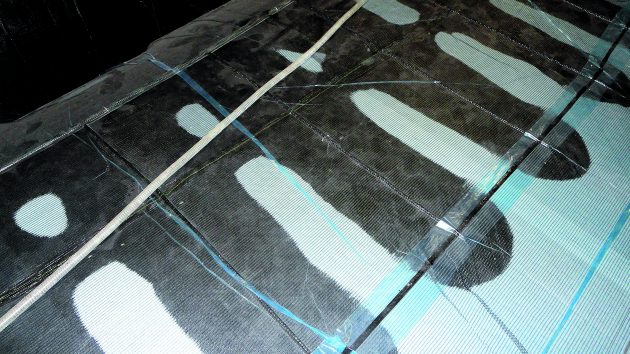

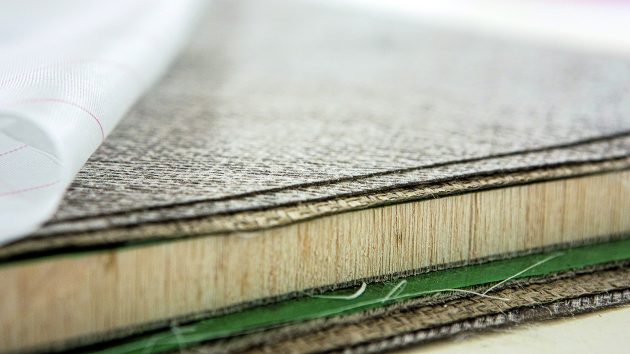

Boat building: what will yachts be made from in the future?

Sam Fortescue shines a light on boat building jargon and looks into a future devoid of fibreglass  Building with pre-preg materials is efficient, but the hull must be 'cooked' at a precise temperature to cure it. Credit: Eva-Stina Kjellman The end of GRP? Sam Fortescue looks at past, present and future boat building materials Glance at a brochure for a new boat or walk the pontoons at the Southampton show and you may have come across some terms that didn’t mean much to you. The art of boat building is as recognisable as ever, but the science of it is constantly developing. New materials and new techniques can make it hard to compare like with like. Take wood, for instance: the material of boatbuilding choice for millennia. There are still plenty of wooden boat-builders out there, labouring away in dingy sheds and halls to craft pilot cutters, rowing skiffs and other emblematic vessels of yesteryear. But perhaps the best known of the wooden boatbuilders is Spirit Yachts in Ipswich, building thoroughly modern boats – in composite wood.  The Spirit 44E is a ‘zero carbon’ cruising yacht. Credit: Richard Langdon ‘Certainly we use epoxy resin to bond the components together, but the amount of resin used is minute compared to GRP or carbon,’ says founder and head designer Sean McMillan. ‘Both carbon-fibre and GRP rely totally on being saturated with a high density of polyester or epoxy resins to impart structural integrity. Wood, whilst also a linear fibre material, is cross-linked with a cellular structure entirely created by nature and has full structural integrity in its own right.’ In fact, the 1.6-tonne Spirit 30 daysailer employs just 73kg of resin and 12.2kg of hardener in its entire construction. ‘In 20 years’ time, when GRP has become socially unacceptable – not to mention any future end-of-life legislation – who knows, we may look back and see the last 60 years of GRP boats as a historical niche,’ finishes McMillan defiantly. Another example is racy French builder RM Yachts, whose boats are famously swift, with offshore hulls designed by Marc Lombard. And yet they are built in plywood and epoxy.  Thought every Spirit yacht us built of wood, it is a composite of glue and epoxy sheathing. It is flexible, robust and far more sustainable than standard glass-reinforced plastic. Sheets of laser cut Okoumé plywood up to 22mm thick are bent around a mould and epoxied to plywood structural members. The whole lot is also epoxy sheathed for longevity. It’s a technique which means that the brand-new RM 1380 is 9.8 tonnes light – slightly less than the comparable X4-6 from X-Yachts. ‘Plywood is the soul of an RM. It a very useful material, allying a good stiffness with lightness – perfect for building the hull and the structure,’ says head of engineering Edouard Delamare. ‘But plywood is nothing without epoxy, because it ensures the waterproofing – vital in a marine environment.’ Boat building using glass-reinforced plasticMany series production yards, from Beneteau to Bavaria , still use the most basic form of wet lay-up – splurging resin on to mats of glassfibre with a roller to get them well wetted out before laying down the next layer of glass. It is very hard to control how much resin is applied and there are often air pockets between layers. For this reason, hulls built this way tend to be overbuilt and heavier.  RM Yachts is unique in building its offshore yachts in plywood and epoxy Polyester is the cheapest and most commonly used resin, but it can bond with water, creating the problem of osmosis. That’s why isopthalic gelcoats are applied to the outside of the hull, to act as an effective barrier to moisture. Vinylester creates many more bonds than polyester and is reckoned to be up to three times stronger, but it costs more too. And epoxy is the best performing resin of all, used only in high-quality lay-ups. All are pretty toxic, and sport the ‘dead-fish’ icon on the side of the tin. When vacuum infusion emerged as an industrial technique in 1990, it allowed boatbuilders to use less resin and spread it more evenly around the finished panel for greater strength. But it generates a lot of waste, because each infused part has to be prepared with a host of plastic layers. Besides the plastic of the vacuum bag itself, there’s a breather layer to distribute the resin and a peel ply to stop it sticking to the infused part; a thick bead of sealant tape; disposable feeder tubes are required every few inches, and many of the vacuum tubes must also be binned. The technology has not stood still, though, and there are now reusable vacuum bags made from inert silicon, for instance. Some bags have the mesh structure necessary to spread the resin built in, while the aerospace sector has pioneered the use of PTFE membrane that stops resin clogging up the vacuum pump side of the system. Sweden’s Arcona builds its fast cruisers using vacuum infusion, and has for many years.  Hand lay-up is a process that has changed little over the years of boat building But in order to add strength and stiffness, it laminates in a steel support frame amidships to transfer the loads from the rig into the keel. Improvements in lamination techniques mean that the boats are lighter than ever. Late Arcona designer Stefan Qviberg said the current Arcona 40 displaced a whole tonne less than its equivalent a decade earlier. Other boat builders use other types of reinforcing for the high-load areas of the hull. Aramids like Twaron and Kevlar often feature, as do selective areas of carbon-fibre on stringers and around keel bolts and chainplates. High-end yacht builder Baltic uses carbon reinforcing, for instance, to add strength without extra weight.  Vacuum infusion uses less resin but creates a lot of plastic waste Performance catamaran brand Catana likewise uses Twaron and carbon in its lay-up to save hundreds of kilos; some 700kg in the old Catana 47. Some claim that aramid reinforcing makes a hull safer, for example in the event of collision with a container, but others refute this. Naturally enough, carbon is still the ultimate performance material because of its blend of strength, stiffness and light weight. It is also prohibitively expensive relative to other fibres and very resource-intensive to produce, as it requires temperatures up to 3,000º C and a plastic feedstock. The bulk and waste of the infusion process has led to another step forward in the form of so-called pre-preg materials, where the sheets of fibre used to strengthen the hull come ready-coated with a pre-catalysed form of the resin that reacts very slowly at room temperature. Instead of needing to mix epoxy with hardener and reduce its viscosity with toxic styrene to draw into the mould, a precisely-controlled curing process activates and sets the resin. The result is a stronger, lighter laminate than can be produced through wet lay-up. Gurit’s SPRINT system goes a step further by sandwiching a thin film of heat-activated resin between two layers of fibre.  Windelo uses basalt fibre to strengthen its hulls during the boat building process. It is said to be much less carbon intensive than using glass The advantage of this is that the fibres remain dry until curing so air can be more easily removed under vacuum to produce a laminate with a void content of less than 0.5%. Baltic Yachts uses this technique, building an oven around its hulls to cure them. ‘With one or two exceptions, we haven’t infused a boat for some time,’ says CEO Henry Hawkins. ‘Using Sprint and pre-preg materials saves weight compared to vacuum infusion. With hand lay-up, generally more resin is mixed than needed and a lot gets discarded. This is the same with infusion where resin is lost or wasted in the plastic hoses and pipes and breather film and within the distribution channels.’ Continues below…  The dirty truth about teakTeak is beloved by boat owners and shipyards for decking and yacht building, but any claims that it is sustainably…  ON TEST: Spirit 44e – the sustainable future of sailing?A wooden boat that blazes a trail for modern technology and sustainability sounds too good to be true. Theo Stocker…  What’s the future for derelict GRP boats?With 9,000 GRP boats abandoned in Europe each year, finding disposal solutions isn't easy. Could new technologies be the answer?… Even at this sharp end of the composite business, rapid advances are being made – driven by aerospace and Formula One. ‘We can now take away the expensive autoclaves and ovens – they can cure at ambient or 40-60ºC,’ says Ashley Parkinson, a research engineer with the UK National Composites Centre. ‘It’s a more expensive process to use, but in the high-performance market, it’s worth it.’ Greener compositesNow, there is nothing particularly sustainable about producing glassfibre – a technique that involves heating raw silica to 1,370º C, then pultruding the molten strands onto a bobbin. You can use some recycled glass to lower your emissions, but it is an energy intensive process and it is very hard to extract the raw materials from end-of-life fibreglass. Swiss supplier Bcomp tested alternative natural fibres 10 years ago, when it was a start-up in a garage. ‘Flax turned out to be the best in terms of mechanical properties, soil usage, water requirements and overall performance,’ explains marine and industry manager Paolo Dassi. It actually locks up carbon rather than producing it – as much as 500g of CO2 per kilogram of flax.  Precise cutting is key to reducing fibre wastage in boat building ‘The plant acts as a CO2 sink during its growth. This completely offsets the CO2 emissions of the manufacturing stages.’ Bcomp’s extraordinary growth began when it managed to process the flax stems to be of uniform size and flatness, replicating the grades possible using glassfibre. Its AmpliTex product is available as a unidirectional, stitched biaxial or woven twill, ranging from 200-500gsm. In lamination it is 50% stiffer than glass and just a little weaker, making it an ideal substitute. Couple this with an extra flax mesh called PowerRibs, and you end up with a composite that closely resembles carbon, but with just 25% of the emissions. AmpliTex has already been used in niche boat building projects, including the glorious Flax 27 daysailer by Green Boats of Bremen, which sports cork decking.  Foam sandwich hull construction (green) or balsa core (wood) is much stronger, for little extra weight. Credit: Graham Snook/Yachting Monthly It was a key part of the lay-up of the new Café Racer 68 from Baltic. Although her hull is in carbon, 50% of the structural members were in flax composite. France’s Windelo has taken a different tack in its catamarans. It uses basalt fibre – made from melted volcanic rock – which ‘is slightly stronger than E-glass and just one-10th as carbon intensive to produce and use’. Its first 50-footer has a hull that also features a recycled PET foam core for strength and stiffness. But it is not just the fibre that is being decarbonised. So-called ‘green epoxies’ have been developed, where a significant chunk of the synthetic oil-derived molecules of the resin are replaced by bio-sourced molecules. Gurit’s Ampro for hand laminating is 40% bio derived, for instance.  Green Yachts focuses on environmentally-friendly boat building techniques. Its Flax 27 is built of sustainable flax fibre And the ProSet range from West Systems includes epoxies containing up to 30% bio molecules. They can essentially just be dropped into any process that would have been suitable for the equivalent synthetic resin. ‘Any customer that is familiar with epoxy processing, vacuum consolidation or post curing will be very familiar with the process,’ says David Johnson of Wessex Resins, European manufacturer for West. ‘Even wet lay-up with no vacuum bagging.’ There is a modest cost increase, but it amounts to less than 25% compared to a standard epoxy, and a drop in the ocean of the boat’s overall build. ‘Bio-based epoxies are more expensive because there’s more sophisticated chemistry involved,’ says Johnson.  Pre-preg flax fibres being laid up around a balsa core ‘Compared to building a boat in vinylester or polyester, you can use slightly less material because of the superior qualities of epoxy. The end cost differences are negligible and there are benefits in lighter weight: you become more efficient, and the loads are less.’ Suppliers like Gurit are also finding ways to substitute the synthetic foam core used in sandwich hull construction. Standard foam is made of virgin PVC, with all the associated environmental pitfalls. Gurit has developed more renewable alternatives using up to 100% recycled PVC and balsa wood. Builders from Arcona and X-Yachts to Bali and Gunboat catamarans use foam cores in their lay-up to build boats that are stiffer and lighter than they would be otherwise. Away from compositesSome innovative new boat builders are going in another direction altogether, eschewing the by-now traditional GRP for something that can be genuinely reused repeatedly. Start-up Vaan is building its 42ft R4 catamaran out of a grade of aluminium alloy commonly used in window frames and road signs, so up to 60% of the hull is already recycled. ‘There’s no way to distinguish it from virgin material,’ says Vaan founder Igor Kluin.  Vaan uses a high proportion of recycled aluminium to build its hulls, which can then be easily recycled It hasn’t been easy to secure supplies, however. That’s partly because window frames last for 50 years or more and also competition with other sectors. ‘In the short term the costs are higher because there are so many people jumping on the bandwagon, but it has only 5% of the energy use of virgin alloy, so in the end it should be cheaper.’ Vaan’s novel approach to sourcing more sustainable materials extends to the interior finish as well. It uses a pineapple leaf fabric instead of leather, plentiful European poplar for cabinetry, cork instead of teak decking and recycled PET.  Greener boat building: A hull made from recycled aluminium Parts of the boat are 3D printed – something that higher end brands are doing more and more of. ‘Recycled industrial PET is being 3D printed for the back of the Vaan spoiler because it produces a lower volume than moulding,’ says Kluin. ‘We want to see if it can become load bearing. We’re also 3D printing with aluminium, too. It’s useful for smaller structural elements that are hard to reach and would traditionally have been milled.’ Recyclability of boat building materialsBesides wood, all forms of composite suffer from the same problem; at end of life, it is very difficult to separate the component materials for re-use. This is why using materials such as steel or aluminium can make sense, despite the higher environmental cost of the virgin metal. They can be reused repeatedly. The composite recycling systems developed to date, which include pyrolysis, burning and shredding, are all unsatisfactory because of the energy intensity of the processes or the fact they yield a lower quality material that has to be downcycled. In principle, it is possible to use resins that melt again at high temperatures and can be collected, refined and reused. Elium resin from Arkema is capable of exactly that, and is already being used in recyclable wind turbine blades.  Laminate are expensive to separate for re-use. Credit: Rob Wilkinson/Alamy Stock Photo They even built a 6.50m Mini Transat boat from it. The process also yields reusable glass, but carbon and flax don’t support the heat: carbon loses as much as two-thirds of its strength and flax simply combusts. However, an Australian study has shown how carbon-fibre composite can first be heated without oxygen in a pyrolysis chamber to burn off resin, then oxidised to yield carbon-fibre with most of the strength of virgin fibre but only 10% of the environmental impact. Cured laminates can also be separated using a chemical process proven in the lab at the National Composites Centre, with a big vat of acetic acid. Portsmouth University is researching enzymes to decompose plastic, starting with plastic bags. The approach could eventually handle boats as well. ‘You have to find the right enzyme that works for snipping the molecules of a particular polymer. Practically, it’s a decade away,’ says Ashley Parkinson of the NCC.  We enable your vision Then you have to be prepared to head off the beaten track.You want a team that feels like family, that can be entrusted to challenge your imagination and be challenged by you. Our ambition is to create and support the most advanced and inspiring yachts in the world. Together. What if you want to go your own way? Oceanco yachts tell the distinctive stories of their owners, who come to us with visions that go beyond the yachts that already exist. Sometimes, even beyond our notions of what a yacht can be.  Bravo Eugenia Black Pearl Tranquility What if we lead a positive change?Innovation is a continuous process of meaningful progress. Our clients come to us because they don’t want yet another iteration from a blueprint, they want a yacht that is theirs and theirs alone. Oceanco achieves meaningful innovation that is aligned with progressive thinking about how we live and the impact on our planet, working with trailblazers from inside and outside the industry to challenge the existing paradigm. We embrace collaboration, partnership and openness while checking our ego at the door.  Tomorrow’s DesignsOceanco partners with luminaries of the creative world to spark your imagination. We plunge ourselves into the deep and don’t come up for air until we have nailed how to transform our bold ambitions into achievable designs.  Cookie preferences

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Yachting World

How (and why) wood is making a comeback in yacht building